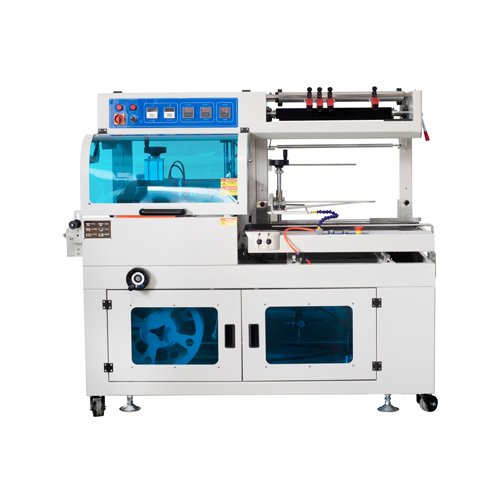

360° Trace-less Shrink Wrap Machine XY-400 | Industrial Shrink Packaging System

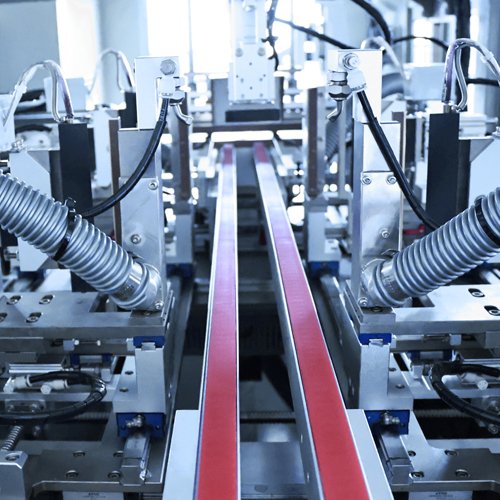

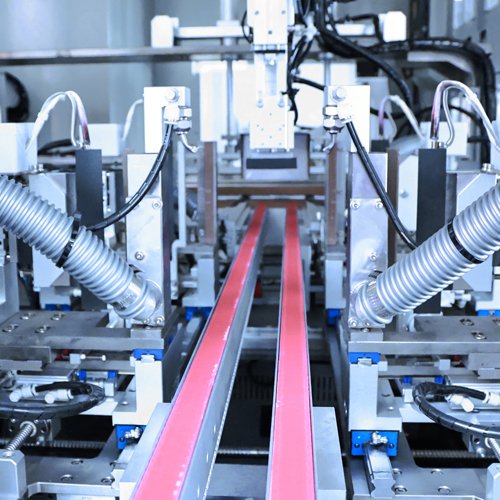

Have a thorough view of the Machinery.

AUTOMATIC INTELLIGENT FILM LAMINATING AND CORNER CUTTING HEAT SHRINK WRAPPING MACHINE

The fully automatic laminating and corner cutting heat shrink packaging machine is designed for efficient packaging of various product boxes. This machine performs two key functions: it cuts the four corners of the packaging and applies heat shrink film after laminating, enhancing the overall appearance of high-end product boxes.

Key Features:

- Automated Process: The machine utilizes non-standard automation technology to seamlessly cut the corners of packaging boxes and apply heat shrink film, ensuring a smooth and efficient operation.

- 360° Shrinkage Effect: The heat shrink packaging provides a flawless 360° shrinkage effect without wrinkles, giving your products a polished and professional look.

- Versatile Applications: This machine is ideal for a wide range of products, including:

- Medicine boxes

- Food boxes

- Health care product boxes

- Cosmetic boxes

- Tea boxes

- Mobile phone boxes

- Power bank boxes

- Tablet computer boxes

- Moisture and Aesthetic Protection: The laminating and heat shrink packaging not only enhances the visual appeal of the products but also provides moisture-proof and protective qualities.

This fully automatic laminating and corner cutting heat shrink packaging machine is the perfect solution for businesses looking to improve the presentation and protection of their high-end product packaging.

Key Features of XY-400 Automatic Shrink Wrap Machinery

- 360° full body shrink wrapping (No visible traces)

- Seamless film shrink finish without overlap or marks

- Fully automatic sealing, cutting, and shrinking workflow

- Supports PE, POF, PVC shrink wrapping films

- High stability for 24/7 industrial production lines

- Tunnel conveyor compatible for uniform shrinking

- Minimum film wastage and reduced operational effort

- Clean shrink result for retail and export bundling

How XY-400 Works

Products move through the infeed conveyor, the machine wraps them with shrink film, creates a clean seal, transfers them into the heat chamber or connected shrink tunnel, and shrinks the film evenly from all sides. The result is a tightly wrapped, 360° trace-less shrink package, ideal for industrial handling and retail display.

The XY-400 shrink packaging system is ideal for industries requiring clean film shrink finish with no visible overlap, no overlap lines and no corner traces, creating premium retail-ready packages without compromise.

Frequently Asked Questions

Q1: Does XY-400 give full 360° shrink wrap without marks?

Yes. The system is engineered for 360 degree trace-less shrink wrap machine, giving a clean finish with no overlap, no traces and no visible seam marks on boxes.

Q2: Can it integrate with a shrink tunnel line?

Yes. It works with Shrink Tunnel conveyor systems for uniform heating, allowing consistent shrink finish output for industrial production lines.

Q3: Is there any film overlap or corner traces after shrinking?

No. The machine delivers trace-less shrink coverage with no film overlap traces, folds, or edge lines.

Machine Durability

Built with high-grade industrial materials, our packaging machines are engineered for long service life.

Efficiency & Speed

Increase packaging productivity with our high-speed shrink wrapping and sealing technology.

Safety Protocols

Safety is at the core of our machine design, featuring advanced protection systems.

Machine Maintenance

Designed for hassle-free maintenance, our machines offer easy part access, minimal servicing needs, guided technical support.

Energy Consumption

Optimized for efficient energy use, our heat-based shrink and sealing systems deliver strong packaging results while reducing power consumption.

ROI & Cost Efficiency

Minimal film wastage improves Heat Shrink Packaging Machinery.

Request a Quote for Your Packaging Project Today

Purchasing packaging machine can be complex. Here are some tips to avoid pitfalls when selecting a supplier for high-quality equipment and excellent after-sales service.

- Research and Check Reviews

- Learn More About Manufacturers

- Arrange On-Site Visits

- Ensure Thorough After-Sales Support

- Timely Delivery