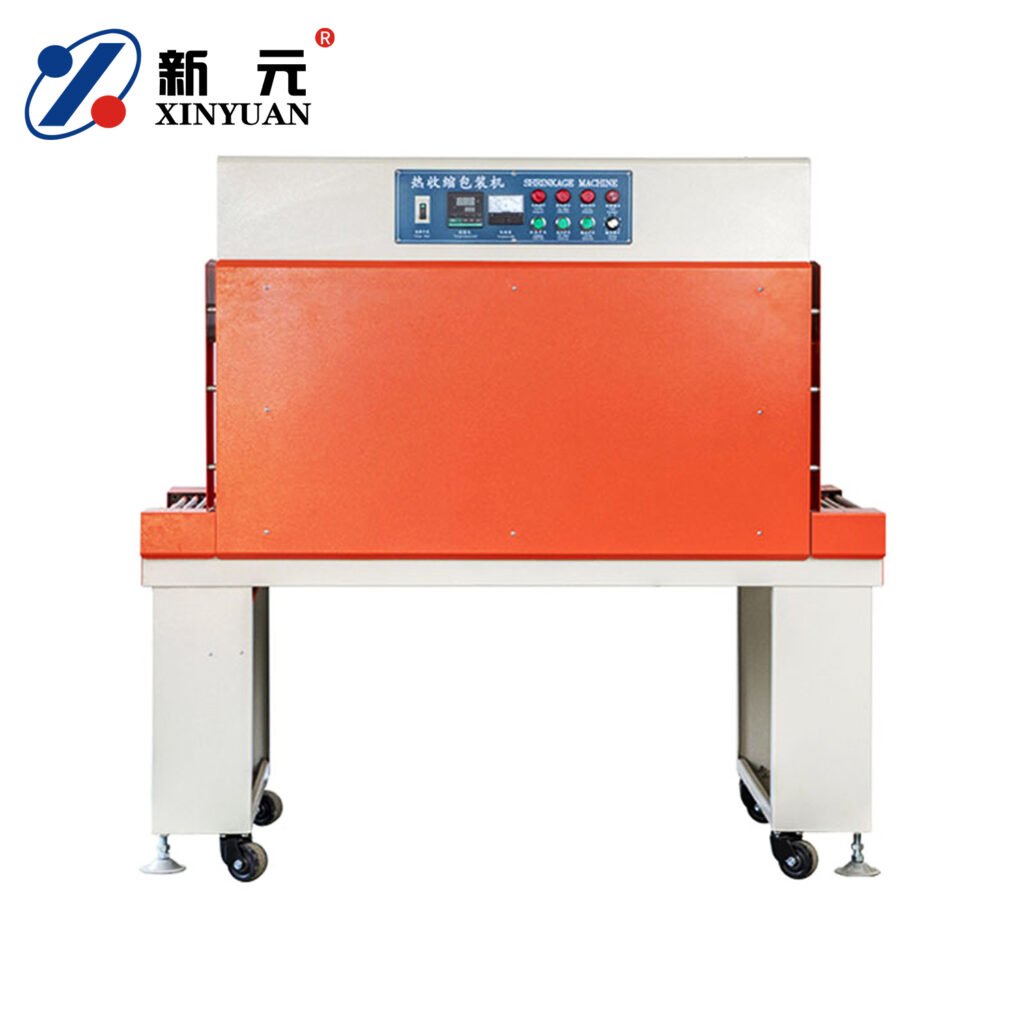

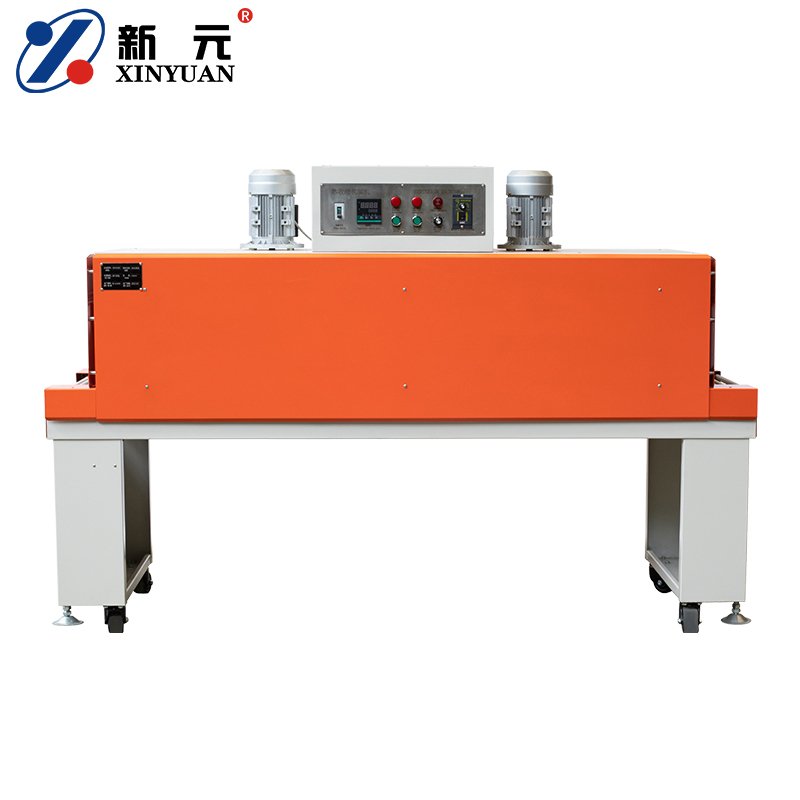

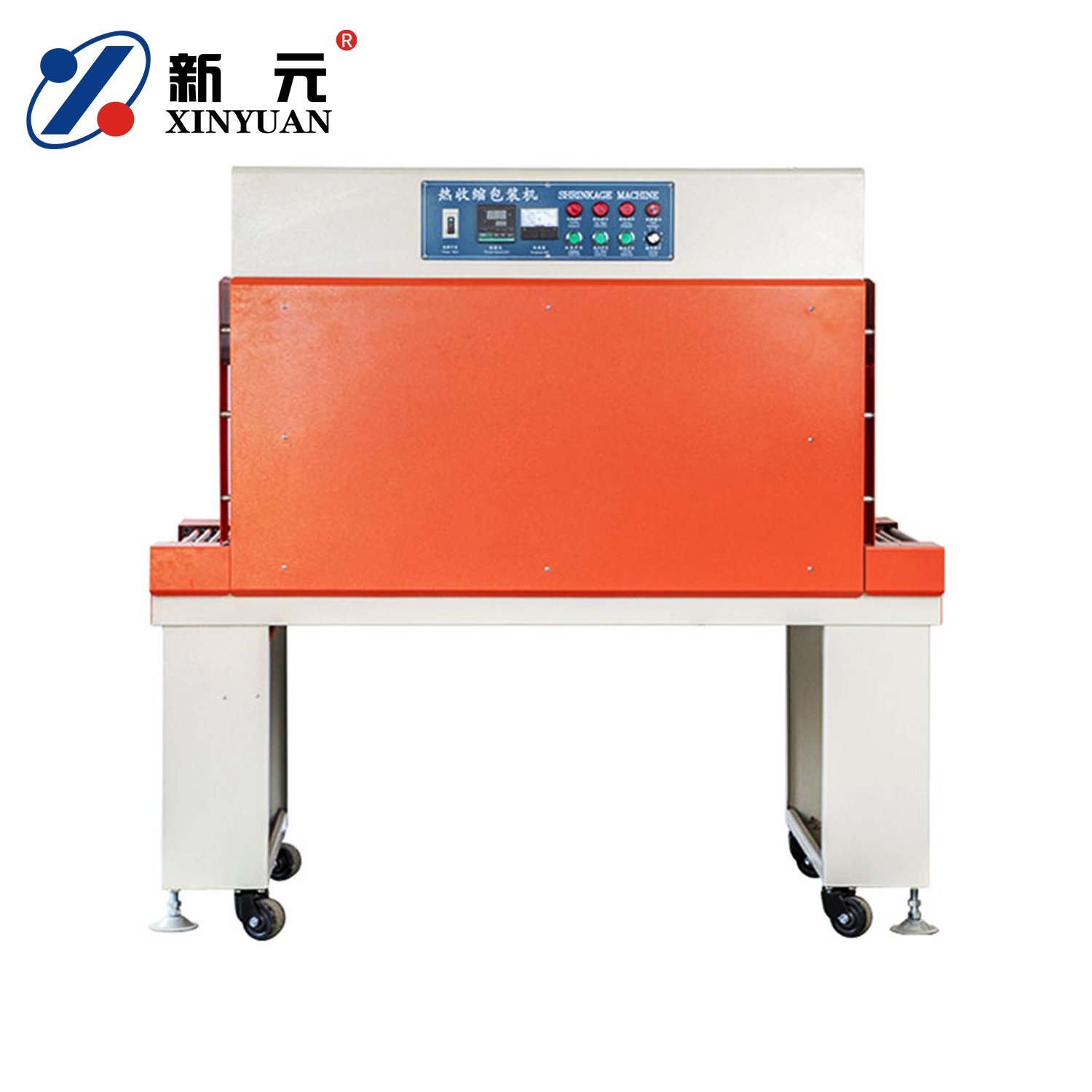

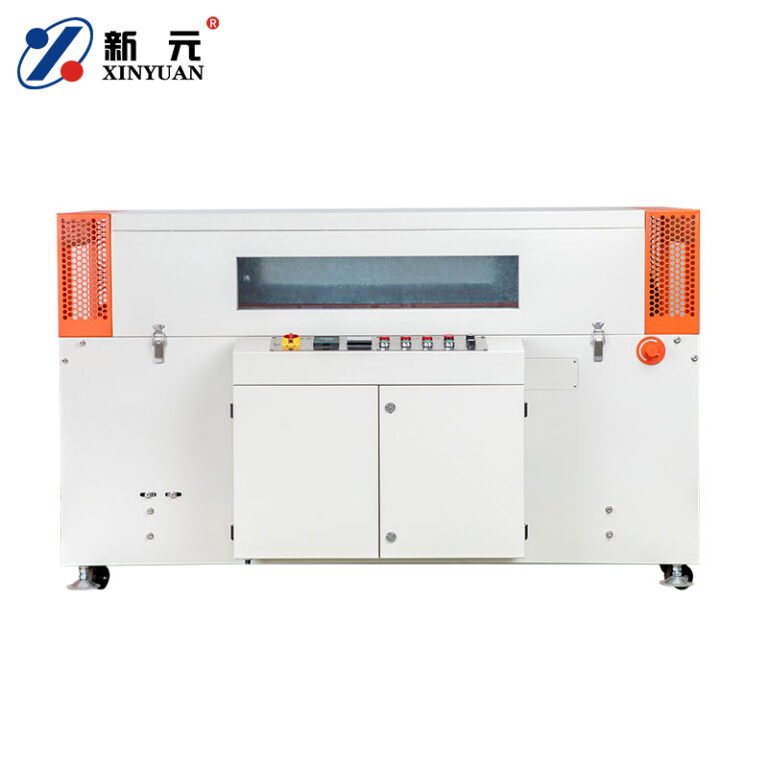

Jet Type Heat Shrink Tunnel – BSP Series Heat Shrink Tunnel Machine

Have a thorough view of the Machinery.

Heat Shrink Tunnel

BSP Series

JET TYPE HEAT SHRINK PACKAGING MACHINE

The BSP Series Jet Type Heat Shrink Tunnel is an advanced industrial packaging machine designed for efficiency and reliability in shrink wrapping applications. This heat shrink tunnel has intelligent safety systems with automatic fault alarms for phase loss, errors, and short circuits, ensuring smooth production. Engineered with a premium stainless steel heater and high-power wind motor, the BSP machine rapidly achieves optimal temperature while maintaining even airflow distribution. Ideal for packaging operations requiring consistent shrink results, this tunnel adapts to various product dimensions through adjustable conveyor speed and chamber temperature controls. Businesses seeking to enhance packaging line efficiency will find the BSP Series shrink tunnel delivers professional finishing for retail, food, pharmaceutical, and industrial products wrapped in PVC, PP, or POF shrink films.

Key Benefits:

- Advanced Safety Systems: Automatic fault detection prevents damage and downtime

- Rapid Heating Technology: Stainless steel heater reaches optimal temperature 30% faster

- Energy Efficient Operation: Double-layer heat insulation reduces energy consumption by 35%

- Versatile Film Compatibility: Works perfectly with PVC, PP, and POF shrink films

- Heavy-Duty Construction: Solid conveying chain roller supports up to 60kg without distortion

| Specification | Model BSP6040 | Model BSP11040 (Customizable) |

|---|---|---|

| Power Voltage (V~/Hz) | 380V / 50-60Hz | 380V / 50-60Hz |

| Power (Kw) | 18 KW | 39 KW |

| Conveying Speed (PCs/h) | 0 – 15 m/min | 0 – 15 m/min |

| Tunnel Size (L×W×H) (mm) | 1800 × 600 × 400 mm | 1800 × 1100 × 400 mm |

| Product Size (Max) (mm) | 550 × 350 mm | 1050 × 350 mm |

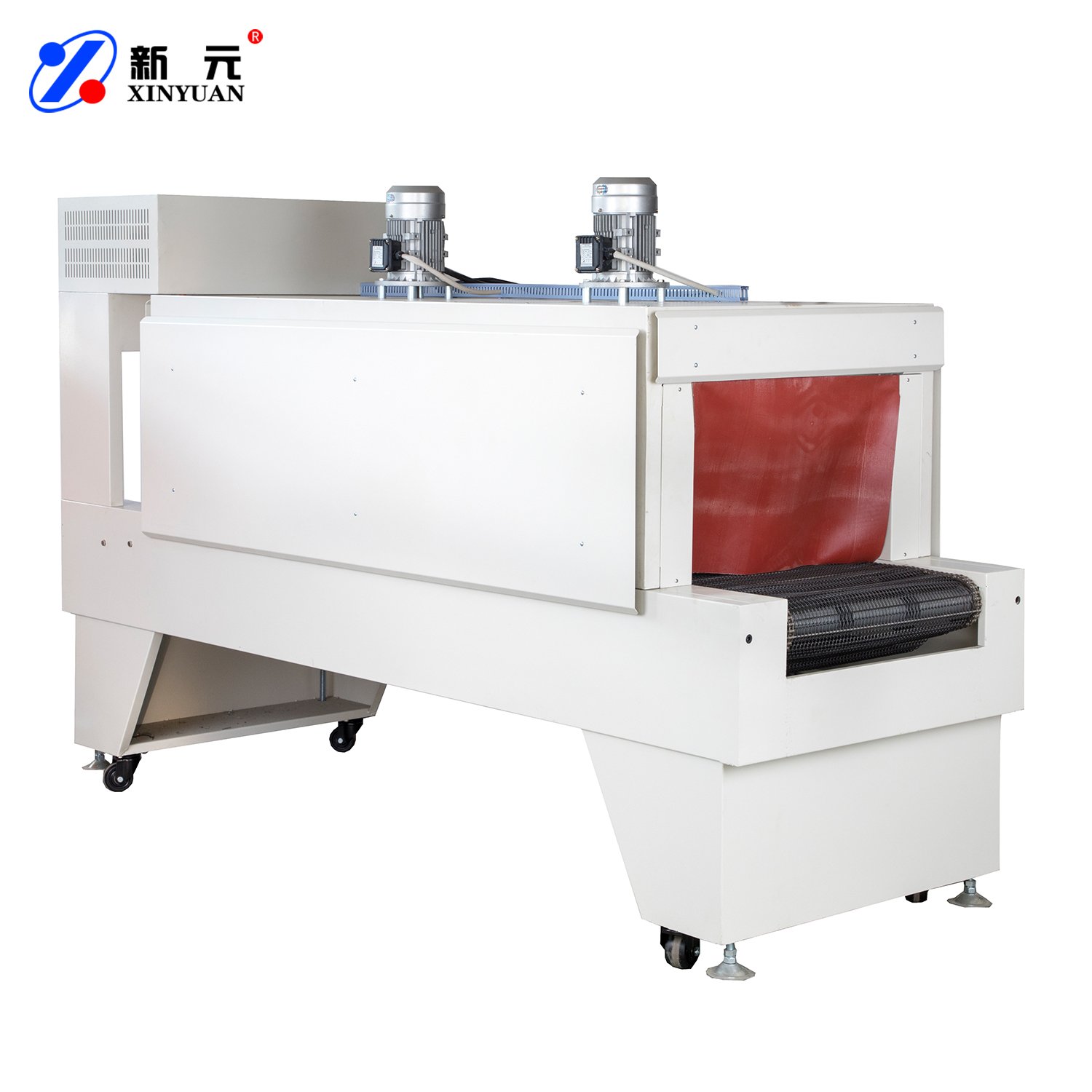

| Conveyor Material | Mesh Belt, Roller Chain, Teflon | Mesh Belt, Roller Chain, Teflon |

| Conveying Load (Max) | 25 kg | 50 kg |

| Machine Dimensions (L×W×H) (mm) | 2500 × 900 × 1650 mm | 2500 × 1400 × 1750 mm |

| Machine Weight | 420 kg | 700 kg |

| Applicable Shrink Film | PE, POF, PVC, PP | PE, POF, PVC, PP |

Technical Specifications:

| Feature | Specification | Benefit |

|---|---|---|

| Heating System | Stainless Steel Heater with High-Power Wind Motor | Fast, even heating with consistent airflow |

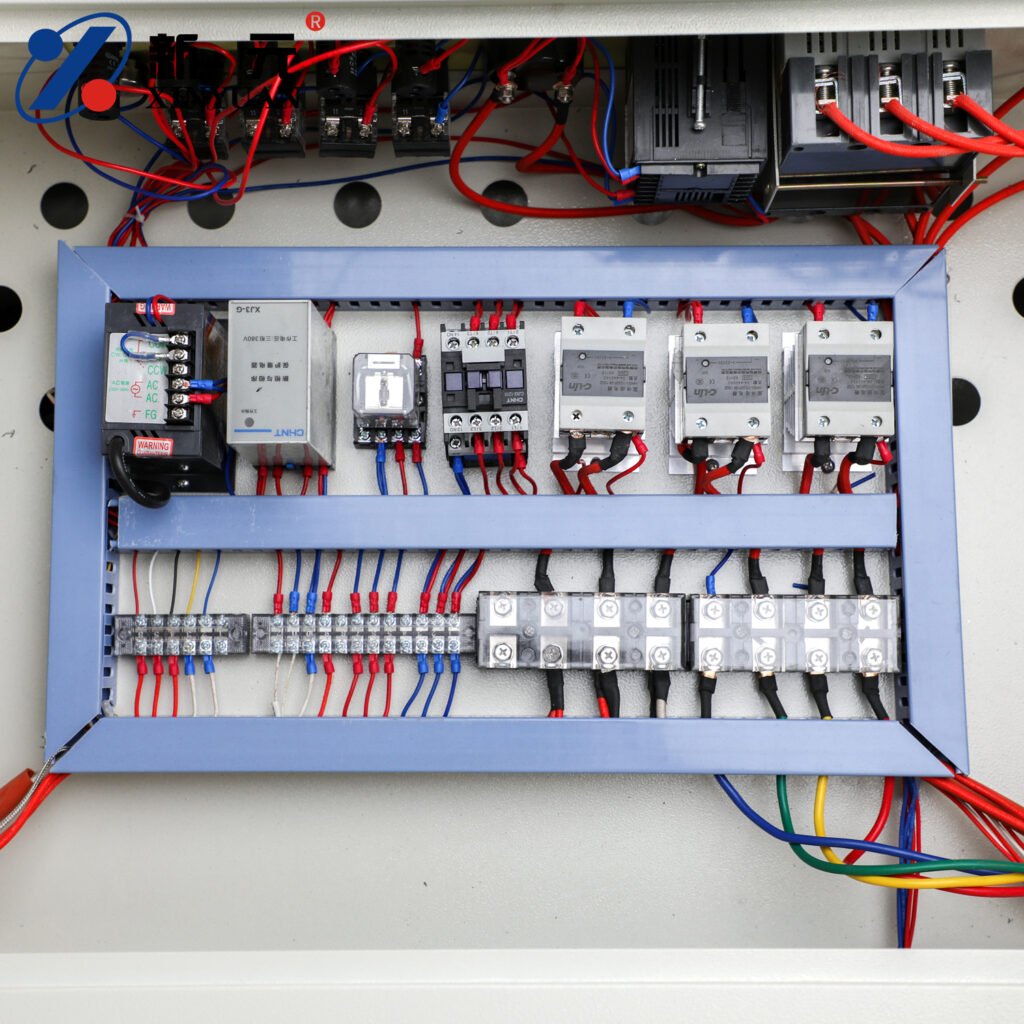

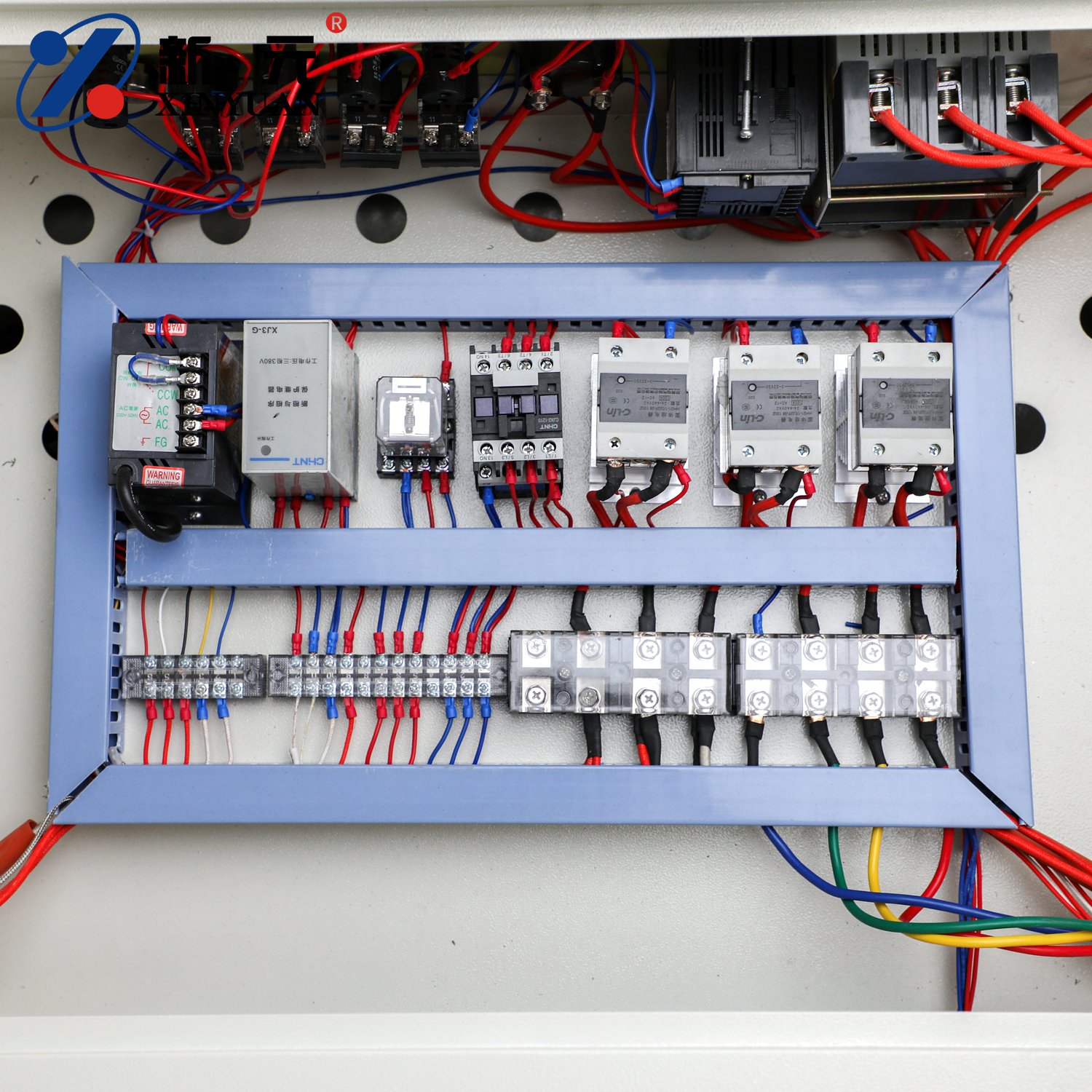

| Safety Features | Automatic Fault Alarms (Phase Loss/Error/Short Circuit) | Prevents electrical damage and production stoppages |

| Insulation | Double-Layer Heat Insulation + High-Temperature Insulation Cord | Exterior remains cool, reduces heat loss by 40% |

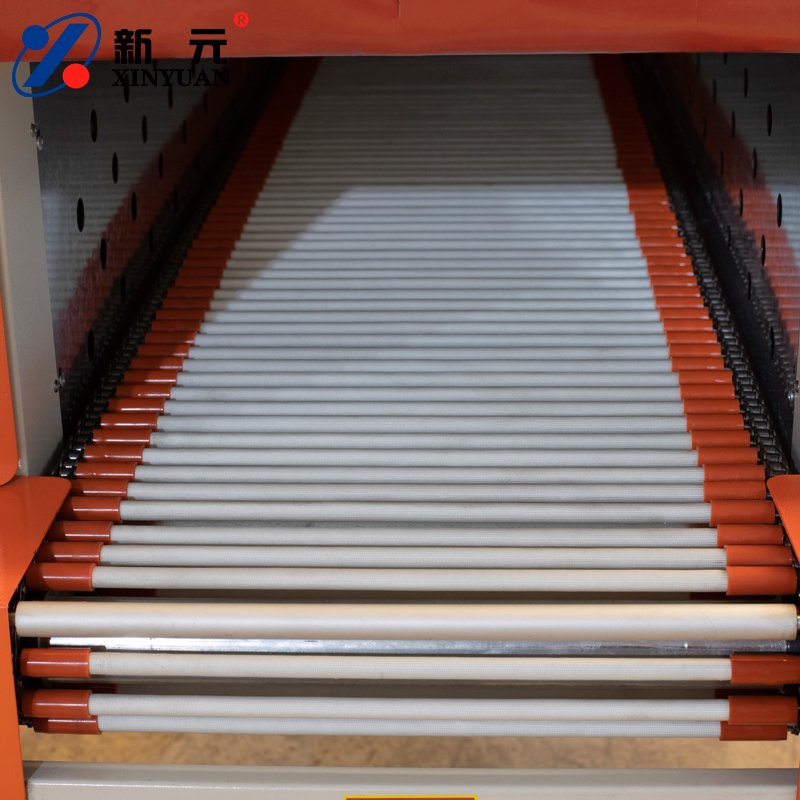

| Conveyor System | Electronic Speed Governor + Silicone-Covered Chain Roller | Smooth speed adjustment, heavy load capacity |

| Film Compatibility | PVC, PP, POF Shrink Films | Versatile for various packaging applications |

| Temperature Control | Adjustable Chamber Temperature | Customizable for different products and films |

| Construction | Industrial-grade steel with protective finishes | Long-lasting durability in production environments |

Industrial Applications for BSP Series Shrink Tunnels

- Food & Beverage Packaging: Ideal for bundling bottles, can multipacks, and tray packaging. Check our Sleeve Package Machine As well.

- Pharmaceutical Products: Secure tamper-evident wrapping for medical supplies and boxes

- Retail Consumer Goods: Professional packaging for cosmetics, electronics, and hardware products

- Publication & Media: Shrink wrapping for books, magazines, and software packaging

- Promotional Items: Multi-product bundles and seasonal packaging with clear film display

Film Compatibility

The BSP Series heat tunnel is engineered to deliver exceptional results with three primary shrink film materials:

- PVC Shrink Film: Crystal clarity for retail display with excellent sealing properties

- PP Shrink Film: Superior strength and durability for heavy or sharp-edged products

- POF Shrink Film: Environmentally-friendly option with high shrinkage ratio and clarity

Know more about different types of shrink films Read this article “https://durapak.net/three-types-of-shrink-films-you-should-know-about/“.

Detailed Features

Precise Conveyor Speed Control & Durability

Featuring an electronic speed governor, the BSP shrink tunnel allows precise adjustment of conveyor belt velocity from 0-20 meters per minute to match specific product requirements and production speeds. The solid conveying chain roller, protected with a durable silicone tube covering, maintains stability under heavy loads up to 60kg.

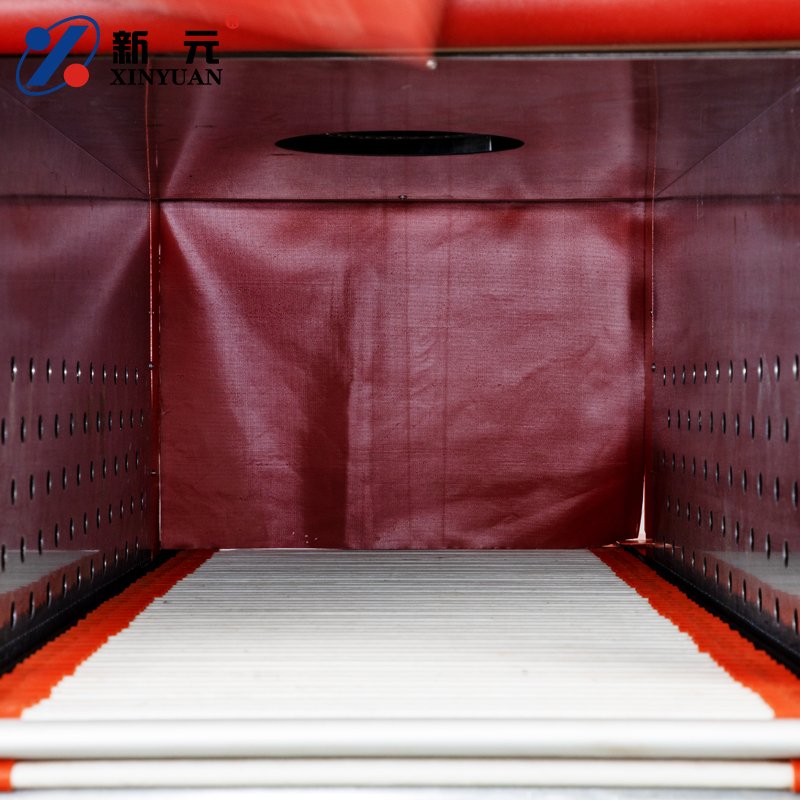

High-Efficiency Heating & Insulation Design

Utilizing a premium stainless steel heater paired with a high-power wind motor, this shrink tunnel machine achieves rapid temperature stabilization while ensuring even heat distribution throughout the chamber. The innovative double-layer heat insulation device, significantly reduces thermal energy loss by approximately 40%.

Advanced Safety Monitoring

The BSP Series heat shrink packaging machine features comprehensive safety monitoring that automatically detects and alerts operators to phase loss, phase errors, and short circuits. This proactive fault alarm system prevents electrical damage to components and eliminates unexpected production stoppages, ensuring your packaging line maintains consistent output

Frequently Asked Questions About BSP Heat Shrink Tunnels

What safety features does the BSP Series include?

The BSP heat shrink tunnel features automatic fault alarms for phase loss, phase errors, and short circuits, plus double-layer insulation that keeps the exterior cool to prevent burns.

Can this shrink tunnel handle different product sizes?

Yes, with electronic speed control for the conveyor belt and adjustable chamber temperature, the BSP easily adapts to various product dimensions and quantities.

What types of shrink film work with the BSP Series?

This machine is compatible with PVC, PP, and POF shrink films, making it versatile for different packaging requirements and product types.

How energy-efficient is the double-layer insulation?

The high-temperature insulation cord and double-layer design reduce heat loss by approximately 40%, significantly lowering energy consumption compared to standard shrink tunnels.

Is the conveyor system durable for heavy products?

Yes, the solid conveying chain roller with silicone tube covering supports heavy objects up to 60kg without distortion or tracking issues.

Request a Quote for Your Packaging Project Today

Purchasing packaging machine can be complex. Here are some tips to avoid pitfalls when selecting a supplier for high-quality equipment and excellent after-sales service.

- Research and Check Reviews

- Learn More About Manufacturers

- Arrange On-Site Visits

- Ensure Thorough After-Sales Support

- Timely Delivery