“BSG Series High-Speed Thermostatic Heat Shrink Tunnel Machine | Newera Pack “

Have a thorough view of the Machinery.

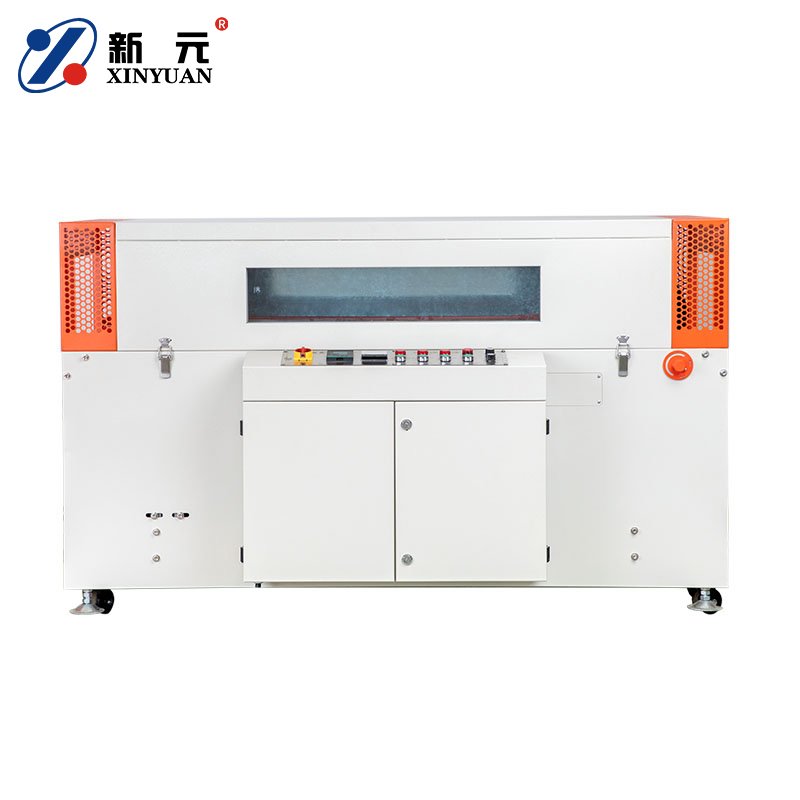

Heat Tunnel

BSG Series

HIGH SPEED THERMOSTATIC SHRINKING MACHINE

The BSG Series Heat Shrink Tunnel is an advanced high-speed thermostatic shrinking machine designed for precision packaging applications. This industrial shrink tunnel system delivers optimal performance, reliability, and efficiency for wrapping boxed products, retail packaging, and industrial items. Engineered with cutting-edge technology and premium components, our BSG shrink tunnel ensures uniform heat distribution, consistent sealing results, providing professional finish packaging solutions.

Key Features:

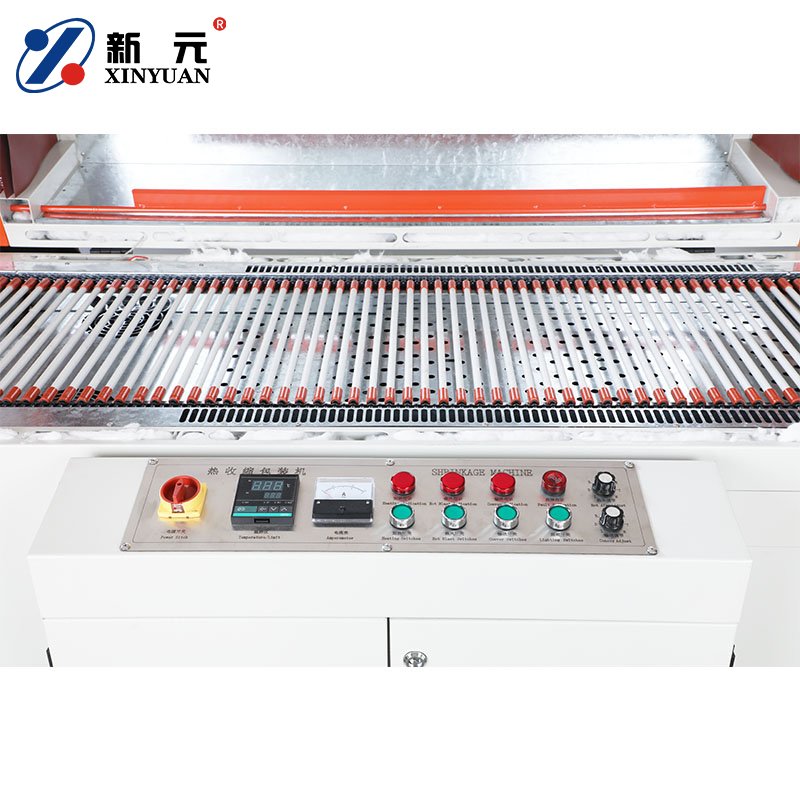

- Precise Temperature Control: PID fuzzy control maintains consistent heat levels (±1°C accuracy)

- High-Speed Operation: Processes up to 30% faster than conventional shrink tunnels

- Energy Efficient Design: Solid State Relay technology reduces power consumption by 25%

- Durable Construction: Stainless steel heating pipes ensure long-term reliability

- Versatile Application: Handles various film types including POF, PE, and PVC shrink films.

This advanced shrink tunnel system is ideal for businesses seeking efficient, reliable, and precise shrink packaging solutions.

|

MODEL |

BSG-5030SL |

|---|---|

|

Power Supply Voltage ( V-Hz) |

380V / 50–60Hz |

|

Power (kW) |

13.6kW |

|

Tunnel Size (L × W × H) |

1500 × 500 × 300 mm |

|

Capacity (PCS/H) |

0–15 m/min |

|

Transport Material |

Roller Chain |

|

Conveying Load |

30kg |

|

Weight |

120kg |

Why Choose the BSG Series Heat Shrink Tunnel for Your Packaging Line?

BSG Series vs. Conventional Shrink Tunnels

|

Features |

BSG Series |

Conventional Tunnels |

|---|---|---|

|

Temperature Control |

PID Fuzzy Control (±1°C) |

Basic thermostat (±10°C |

|

Heating Element Life |

10,000+ hours |

3,000-5,000 hours |

|

Energy Efficiency |

25% more efficient |

Standard consumption |

|

Speed Adjustment |

Precise digital control |

Manual mechanical adjustment |

|

Maintenance |

Modular, tool-free access |

Complex disassembly required |

|

Cooling System |

Time-delay protection |

Immediate shutdown |

Learn more about Heat Shrink Tunnels click here.

Industrial Applications of BSG Heat Shrink Tunnel:

Our BSG Series is ideal for:

- Food & Beverage Packaging: Bottle bundling, tray packaging, multipack solutions

- Pharmaceutical Products: Sterile packaging, security sealing, tamper-evident wrapping

- Cosmetics & Personal Care: Boxed products, promotional bundles, retail displays

- Electronics & Hardware: Protective wrapping, retail packaging, moisture sealing

- Publishing & Media: Magazine multipacks, book wrapping, DVD/Blu-ray packaging

See complete industrial solutions by our packaging machines, check out our Video Library & Solutions for Industries Page.

Frequently Asked Questions About Heat Shrink Tunnels

What is the maximum temperature of the BSG heat shrink tunnel?

The BSG Series reaches up to 250°C, suitable for all common shrink films including POF, PE, and PVC materials.

How does the PID fuzzy control improve packaging quality?

The intelligent control continuously adjusts heating pulses based on real-time temperature readings, eliminating hot/cold spots and ensuring uniform shrinkage.

Can the BSG handle different product sizes without adjustment?

Yes, the variable speed conveyor (0-15 m/min) and adjustable airflow system accommodate products from 50mm to 500mm in height without mechanical changes.

What safety features does the BSG include?

Time-delay on-off protection gradually reduces temperature after shutdown, preventing component deformation. Overheat protection and emergency stop are standard.

Is the BSG compatible with existing packaging lines?

Yes, the modular design and standard conveyor heights (500mm, 750mm, 1000mm) allow seamless integration with most production lines.

Free Line Assessment

Our experts will evaluate your current setup

Live Demonstration

See the BSG in action with your samples

Competitive Pricing

Premium quality at competitive investment

Download Brochure

Custom Configuration

Tailored solutions for your specific products

Request Quote Today

Request a Quote for Your Packaging Project Today

Purchasing packaging machine can be complex. Here are some tips to avoid pitfalls when selecting a supplier for high-quality equipment and excellent after-sales service.

- Research and Check Reviews

- Learn More About Manufacturers

- Arrange On-Site Visits

- Ensure Thorough After-Sales Support

- Timely Delivery