“Achieve Flawless, Wrinkle-Free Packaging with Our Heat Shrink Tunnel Machine!”

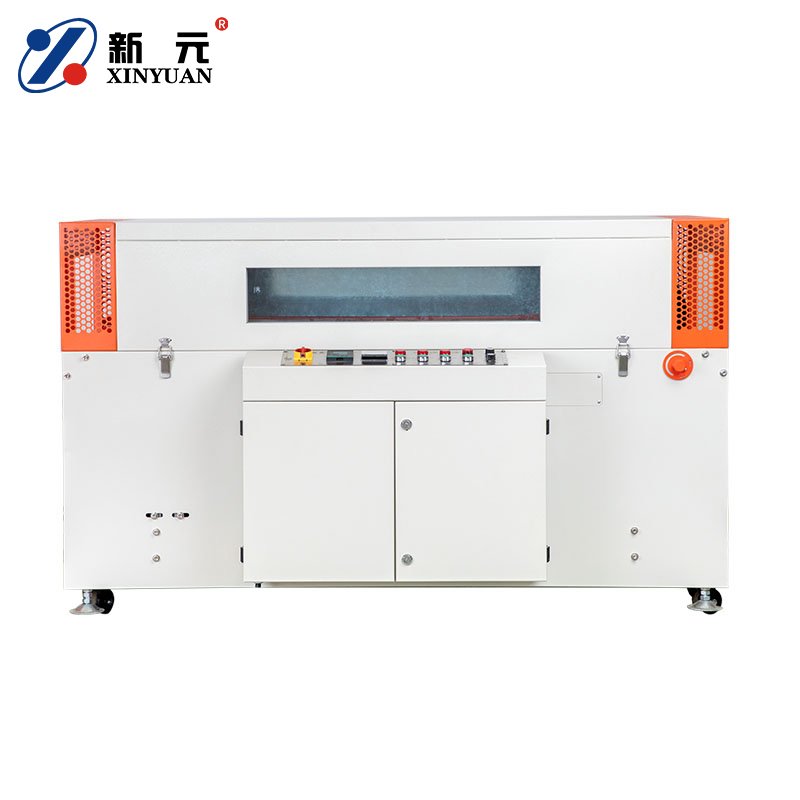

Have a thorough view of the Machinery.

BSG Series

HIGH SPEED THERMOSTATIC SHRINKING MACHINE

Our advanced shrink tunnel system is designed for optimal performance and reliability in packaging applications. It incorporates cutting-edge technology and high-quality components to ensure efficient operation and long service life.

Key Features:

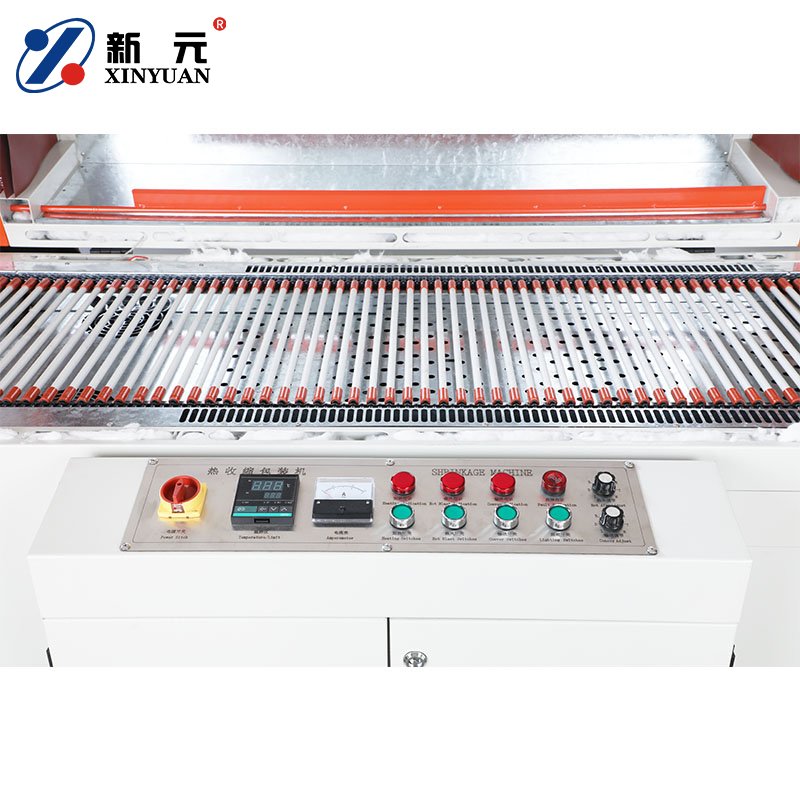

- Solid State Relay: The machine uses an imported high-current solid state relay (SSR) with no contact output, equipped with a specialized SSR radiator. This design significantly improves heat dissipation efficiency and extends the relay’s service life.

- Stainless Steel Heating Pipe: High-quality stainless steel heating pipes are utilized for the heating elements, ensuring stability and reliability throughout the system’s operation.

- PID Fuzzy Control: The temperature controller features a unique PID fuzzy control function that continuously monitors external temperature changes and heat values. It controls the heating tube with minimal pulses for quick response, ensuring precise temperature control and minimizing internal temperature distribution errors.

- High-Power Air Transport Motor: An imported high-power, high-speed air transport motor works in conjunction with a frequency converter to adjust the airflow within the furnace. This allows for customization based on different products and shrink film materials.

- Conveyor Belt Drive Motor: The conveyor belt is driven by an imported speed-reducing motor, paired with a frequency converter for smooth speed regulation. This setup provides high torque and can handle substantial conveying loads.

- Modular Design: The machine features a compact modular design, making maintenance and protection convenient and straightforward.

- Observation Window: A high-temperature resistant lighting bulb is embedded in the furnace, allowing operators to view the shrinkage effect through a glass observation window. This feature enables real-time adjustments to control settings during the shrinkage process.

- Independent Roller Structure: The independent roller structure, combined with a chain roller, ensures smooth operation with a speed adjustment capability of ±10 mm/min.

- Time-Delay On-Off Protection: The system includes a time-delay on-off protection feature that gradually reduces temperature after shutdown, preventing deformation of components due to uneven cooling.

This advanced shrink tunnel system is ideal for businesses seeking efficient, reliable, and precise shrink packaging solutions.

Machine Durability

Crafted with premium materials, our machines promise longevity and consistent performance, ensuring long-term value.

Efficiency & Speed

Maximize productivity with our high-speed wrapping systems, designed for seamless and rapid operations.

Safety Protocols

Safety first! Our machines are engineered with advanced safety measures to protect both operators and products.

Machine Maintenance

With user-friendly designs, our machines are low maintenance. Plus, we offer comprehensive support for any issues.

Energy Consumption

Designed for eco-efficiency, our machines deliver top-tier performance while minimizing energy usage.

ROI & Cost Efficiency

Invest in a machine that not only boosts productivity but also ensures a rapid return on investment, thanks to its cost-effective operation.

Request a Quote for Your Packaging Project Today

Purchasing packaging machine can be complex. Here are some tips to avoid pitfalls when selecting a supplier for high-quality equipment and excellent after-sales service.

- Research and Check Reviews

- Learn More About Manufacturers

- Arrange On-Site Visits

- Ensure Thorough After-Sales Support

- Timely Delivery